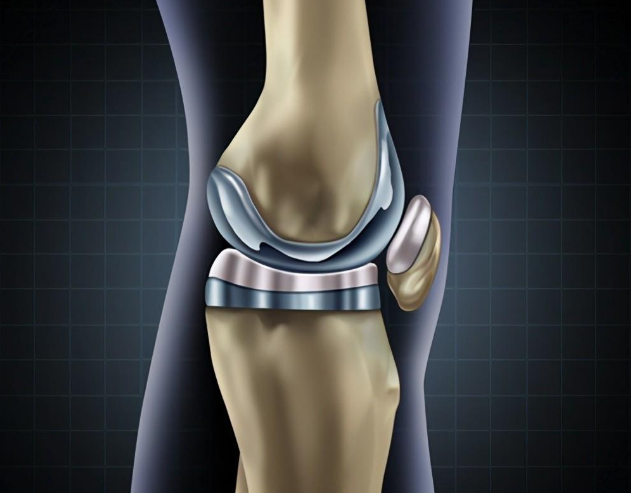

Because of its good biocompatibility, titanium has been chosen as the ideal product for human implants. For more than 10 years, many scientific research departments, medical colleges and hospitals of international countries and China have also done a lot of basic work and clinical scientific research. Titanium is recognized as the most ideal human body implant products from the depth and breadth. In these years, thousands of cases have been recorded in the artificial femoral head, artificial wrist joint, knee joint, artificial dental cultivation, skull repair, cardiac pacemaker and so on made of titanium. After years of research, surveillance and comparison, titanium has been reported so far to be the most ideal product for human implants. welded titanium tube supplier consider The design of orthopedic devices needs to conform to the complex shapes of bones and joints, and therefore the processing of these parts is complicated. These devices, which are made from titanium rods, require a large amount of material to be cut, making the process expensive due to the low machinability index of many materials. As a result, some parts are cast to approximate the final shape of the part, which often requires complex and expensive fixtures.

Titanium 6AL-4V ELI is a standard product for crotch joints, bone screws, knee joints, plate bones or organs, dentures, and surgical equipment. However, cobalt-chromium alloys are increasingly used because of their strength, tighter granularity and cleaner properties than titanium. The cutting forces required to work titanium alloys are only slightly greater than those required to work steel. However, the metallurgical properties of titanium alloys make them more difficult to work than steels of appropriate hardness. Titanium has a work hardening property that eliminates the consolidation of metal (curling) in front of the cutting tool. This helps to increase the shear Angle in machining, thus forming a thin chip that touches the surface of the cutting tool in an appropriately small area. Because of this work hardening, the feed should not be stopped during the tool's motion touch with the workpiece. The large bearing forces that occur during machining, combined with the friction generated by the chips in the touch area, result in a significant increase in heat in the tool part.

The heat from cutting titanium does not dissipate as quickly because it is a poor conductor. As a result, most of the heat will be concentrated on the cutting edge and tool surface. Large bearing capacity and heat, in the cutting edge near the formation of crescent, resulting in quick tool damage. Worse, titanium alloy at the working temperature of the tool, there is a strong tendency to melt alloy or revive chemical changes with the products in the tool, and there is a tendency when the chip bond to the cutting edge of the tool, resulting in the appearance of the tool damage. These difficulties are doubled when the tool begins to break, so tools used to process titanium and its alloys should be carefully monitored to ensure that the blade is sharp and replaced before becoming dull. The experience of processing titanium and titanium alloys is that if you see any change in the process of processing, you should immediately change the tool, because the change means that the tool will become dull. Another reason to stick with a sharp tool is that titanium can cause fire when cutting with a broken or damaged tool. When burned, the metal oxygenates, so the fire ignites itself. Therefore, many titanium processing workshops do not report fire, they are equipped with a saving system on the machine tool.

Titanium has a reasonably low modulus of elasticity and is more elastic than steel, so it tends to violate the cutting tool during machining unless it is used for firm and robust cutting or as a suitable support. Long and thin parts under tool pressure, tend to deflect, resulting in tool chatter, tool friction and poor work. Through the processing experience that the rigidity of the tool system is very important, we should use sharp and accurate shape of the tool. As a result of these pressures, new technologies have been introduced to help the medical parts shop meet the competition and produce these complex parts with great precision; Many innovations in EDM have enabled faster production of high quality parts and eliminated many of the problems inherent in older machining techniques.

As a new product, titanium has only been developed and applied in China's pharmaceutical industry, medical instruments, human implants and other fields for nearly 20 years. However, it has achieved great success, and achieved significant social and economic benefits, and shortened the gap between China and the international advanced countries. The use of titanium equipment in the production of many products not only deals with the serious problems of equipment corrosion, but also greatly improves the quality of drugs.